Aeronautics and space

MECA MAGNETIC’s portfolio includes major global customers such as Thales, Safran E&D but also niche companies such as Orolia, Ixblue…

MECA MAGNETIC knows how to adapt to a multiplicity of needs, whether it is for the development of prototypes and series, security, or technical mastery requirements.

We are structured and able to respond to the problems of : FAI, FMECA, special processes, traceability, repeatability, analysis of non-conformities by the 8D method, REACH & ROHS, compatibility with the requirements of the client, ethical and CSR practices, regular audits of systems or products by our customers…

- Because continuous improvement is for us a key factor of success, we are constantly seeking to better respond to our customers by improving, service rate, quality, response to standards.

A high requirement on the manufacturing processes

MECA MAGNETIC offers a wide range of services enabling us to respond to subcontracting and/or co-contracting issues such as design assistance, tooling management, production and subassembly.

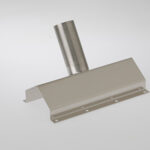

To ensure the needs in low frequency magnetic shielding, we work with the following materials: lead, stainless steel, nickel alloys, aluminium, permimphy, pure iron… for the main applications such as inertial power stations, atomic clocks, LVDT, flow meters…

They trust us

A rigorous support

The vertical integration of a significant part of the manufacturing of low frequency magnetic shielding and a large panel of approved subcontractors allow MECA MAGNETIC to answer in terms of costs, quality, deadlines, but also of processes and possible qualifications to the high requirements of its principals.

MECA MAGNETIC is thus able to fit into the normative framework required by the major principals:

- – Competence and understanding of long product qualification cycles,

– Stakes of securing manufacturing processes and flows,

– Improvement of industrialization,

– Traceability, repeatability, reactivity, record management;

– Process risk analysis and mitigation, quality management and analysis

– Qualification of operating procedures and operators,

– Experienced personnel, support functions and management allowing an understanding of the customer’s issues.

MECA MAGNETIC has set up an HR organization that enables us to meet aeronautical and space requirements: our staff is qualified, supervised by experienced managers and our teams are stable. The organization also ensures its customers a regularity of competences, by a regular follow-up and measurement of the internal competences, training plan (internal and external), follow-up of the versatility, process qualification, parts and special processes and evaluation, anticipation of the retirements.

A key partnership

Historically a player in the aeronautics and space industries, MECA MAGNETIC can as such indirectly serve the defense markets. We thus quite naturally joined the EDEN (European Defense Economic Network) Cluster in 2017.

Created in 2008, the EDEN Cluster is an association of companies that allows its members to pool their industrial and technological skills and thus present the Defense, Security and Safety sector with a complete, solid and relevant offer.

FAQ

Yes, we usually do in our line of business. We also carry out pre-series in the parts qualification process. The pre-industrialization phase allows us to validate the various stages of product definition and industrialization.

We check the attenuations with our Helmhotz coil or with Gaussmeters. In most cases, we offer to provide magnetic value readings on control washers, from the same material batch and having undergone the same heat treatment as the parts delivered.

MECA MAGNETIC, also manages the specificities of the customers’ needs and control documents.

Suppliers are located in France and/or in the European Union, which is also a CSR issue for MECA MAGNETIC. They are used to (and/or certified in) the aeronautics and space sector. Their work practices are therefore reliable. These suppliers/subcontractors are evaluated once a year and exchanges for continuous improvement are regular.

Yes, we have a stock of material that allows us to respond within an optimized timeframe. Meca Magnetic is also able to have dedicated and specific stocks for significant series.

MECA MAGNETIC is certified ISO 9001 since 2009 and continues to be involved in this standard every year, in order to demonstrate its capacity and its commitment in customer satisfaction, quality system, management and continuous improvement.

The last audit demonstrated that the processes put in place continue to be demanding and effective. This certification, issued by TÜV, certifies that the management system in place at MECA MAGNETIC has been evaluated and found to be in compliance with the manufacturing requirements of our low frequency magnetic shields. MECA MAGNETIC is also regularly audited by its aerospace customers.

The dematerialized information is managed via our ERP, which allows us to ensure full traceability of data related to products from the customer order, purchases, stocks, production follow-up, quality, accounting…

MECA MAGNETIC rigorously identifies product and/or order and/or quotation changes (index management) and keeps all data securely in accordance with customer/standard requirements.

Inertial navigation is a self-contained navigation technique in which measurements provided by accelerometers and gyroscopes are used to track the position and orientation of an object relative to a known starting point, orientation and velocity. By processing signals from these devices, an INS can detect a change in its geographic position (a move east or north, for example), a change in its velocity (speed and direction of movement) and a change in its orientation (rotation about an axis). Inertial navigation systems are used in many different moving objects.

An atomic clock is a clock that measures time by monitoring the frequency of radiation of atoms. The accurate timekeeping capabilities of atomic clocks are also used for navigation by satellite networks such as the European Union's Galileo Program.

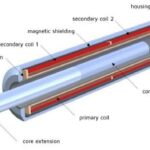

The linear variable differential transformer (LVDT) (also called linear differential transformer) is a type of electrical transformer used for measuring linear displacement (position).

The objective of a flow meter is to have a reliable measurement information on a mechanism working by the creation of an electromagnetic field, which is disturbed by an external magnetic field (magnet, electric actuator for example).

The measurement is performed by a flowmeter, which must be protected by a magnetic shield.